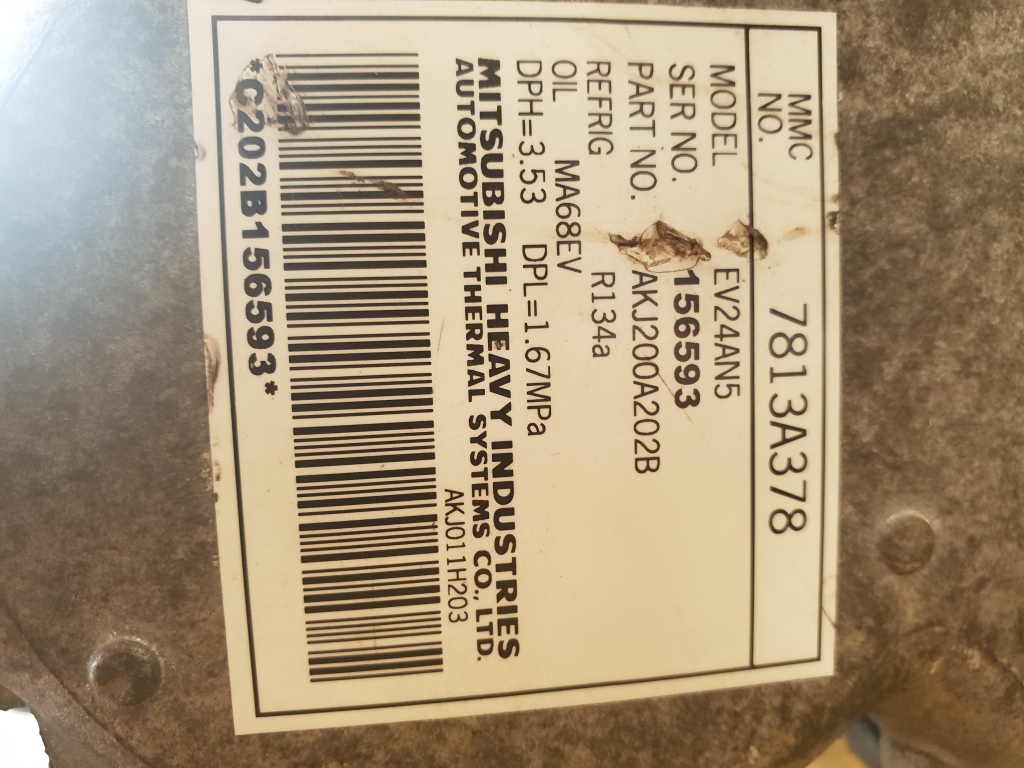

After a lot of time probing the Outlander PHEV AC compressor it finally came to installation. I got compressor off some car dissasembly company and i took it because it also had AC pipes on. This way i will be absolutely certain everything will fit. I had a company weld new fittings to short stubs from original pipes, the kind with cone fit, no O-rings required. On the other side i will use flexible hoses.

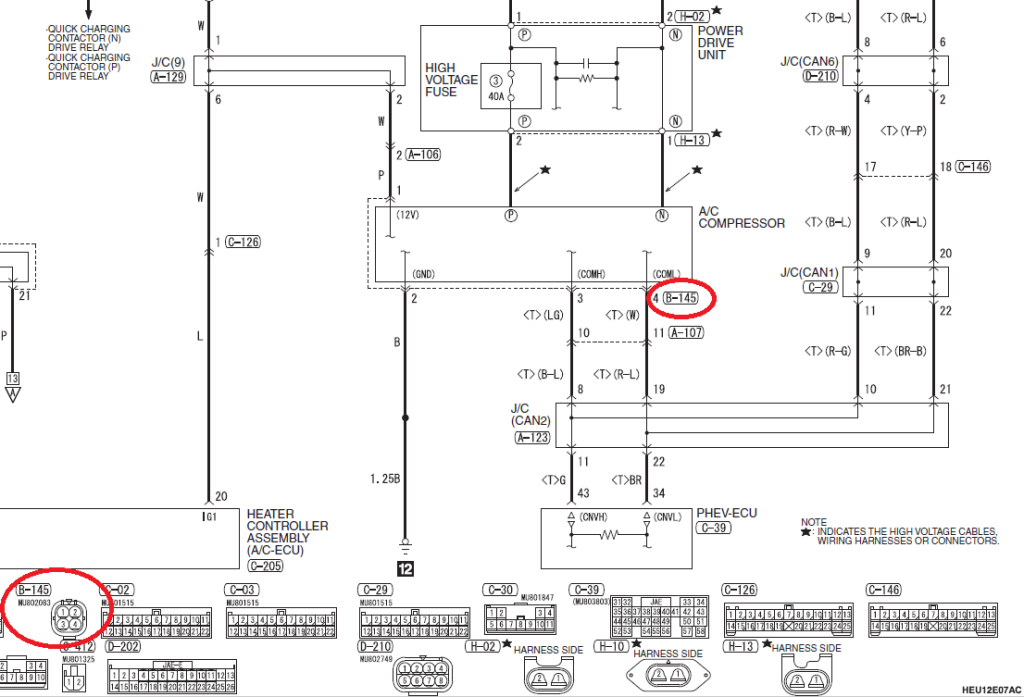

LV connector is the same as with Heater, Sumimoto 4 Way TS Connector Plug, P/N 90980-10942. Top two pins are 12V(1) and GND(2) and other two CANh(3) and CANl(4).

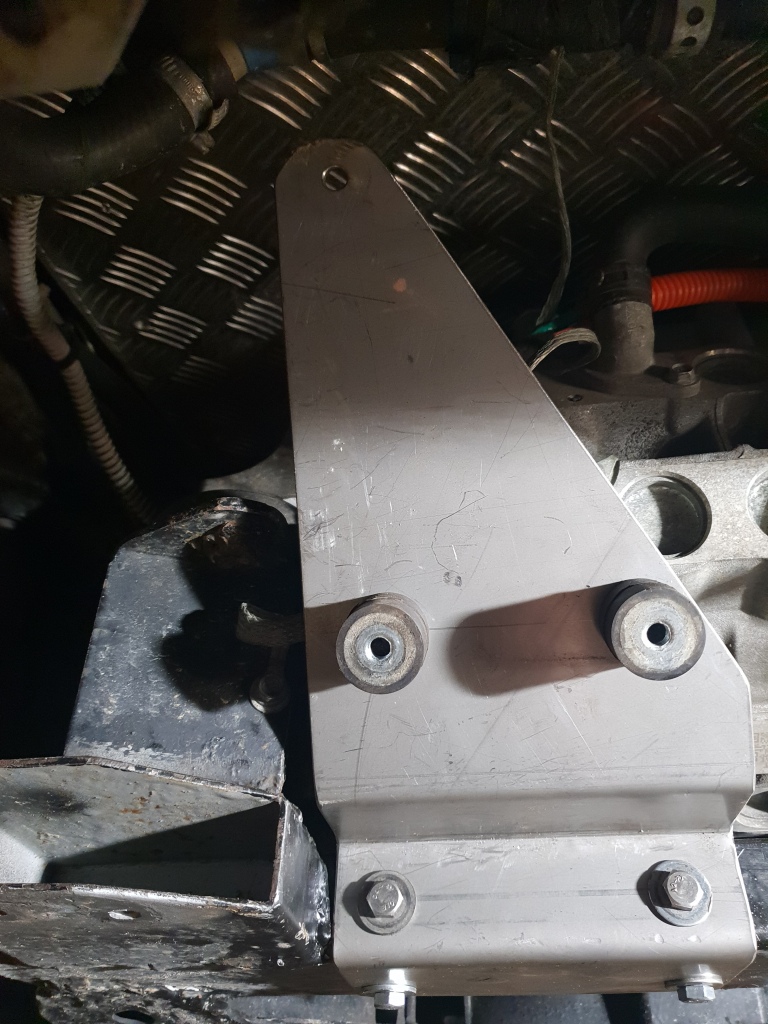

This compressor is a little higher than Prius compressor on account of its inverter. This interfered with previous spot on the side of front motor mount.

I had to build another mount to fit it in front where i had enough vertical space. This time i decided to make the mount from stainless steel 4mm.

I had to fold it on the metal sheet press in my friends workshop. After some deburring and drilling i had a finished product, not neccessary to paint it.

To mount it i needed to think a lot. I could weld 8mm threaded rod to where i drilled the holes and that would allow me to use the stubs with nuts. But i couldnt assemble the mount with rods sticking from two different locations! I needed to fit some nuts from behind sheet metal motor mount bed.

Hex rivnuts to the rescue! Had i found those earlier they would have made my life so much easier. What you have here are your standard rounded rivnuts with M8 threaded nut inside with addition of hex form on the top. To fit this into round 10.8mm hole i drilled for it i needed to file the edges into the hex form and gave it a little tap. A lot of filing, but satisfying work… After that i only needed to put M8 bolt into the nut and torque it to form the rivet part flush with the mount. I am very happy now that i know i can use this with all sort of sheet metal.

I see you can get those on ebay

https://www.ebay.de/itm/274983217641?hash=item400646e9e9:g:064AAOSwR6RaRHBY

Or on Aliexpress

I installed compressor on some rubber blocks with M8 threaded inserts. I also made new flexible hose connections that will allow me to rout new hoses in the engine bay.

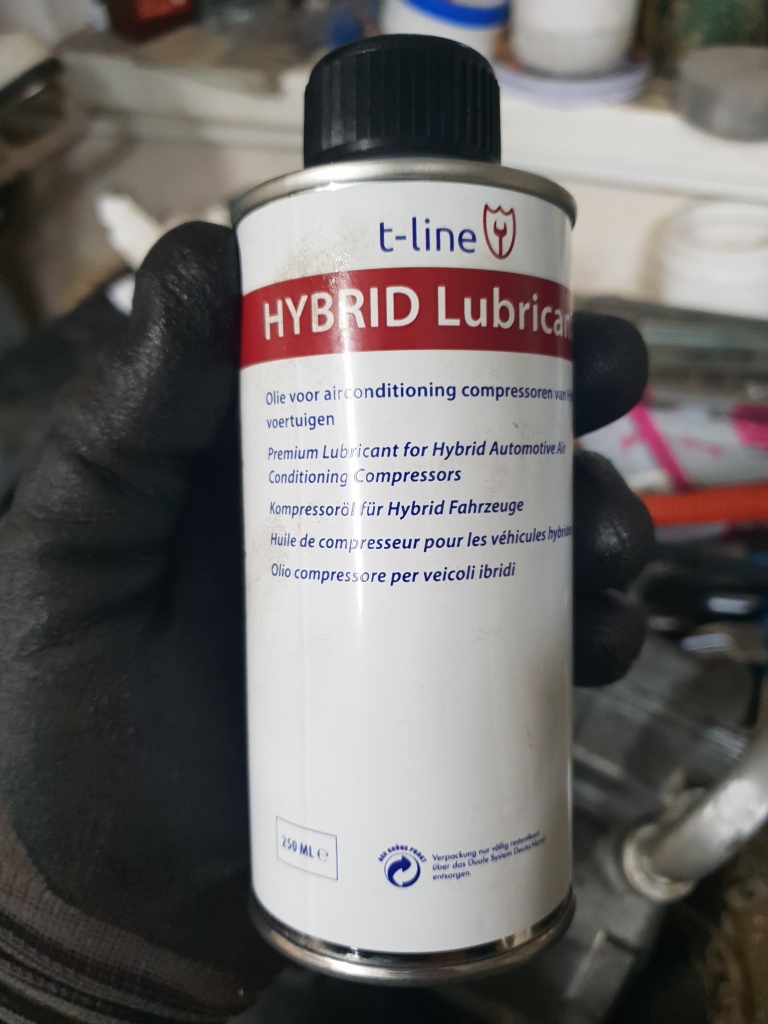

When i had everything prepared i put some Denso ND11 hybrid oil into it. This is neccessary because compressor oil is used to cool its motor. Any other oil may cause wire laquer damage and eventual short in the motor. So no other oil is allowed. I filled 130ml of oil using a syringe. Most of it i pushed in the motor side and at least 30ml i also sent to the compressor side. Compressor will eventually spatter the oil through the hoses also.

I tightened the hoses and connected everything electrical under the car. I am using old AC compressor clutch signal to turn on a relay. This relay i will use to pull DUE signal to GND and this will signal for it to start transmitting correct CAN telegram.

Works like magic. Compressor spools up and runs and when it is not needed anymore is slowly spools down. This is way smoother than before with Prius compressor.